|

| January 23, 2024 | Volume 20 Issue 03 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

U.S. Army gets world's largest metal 3D printer -- already recognized for technical achievement

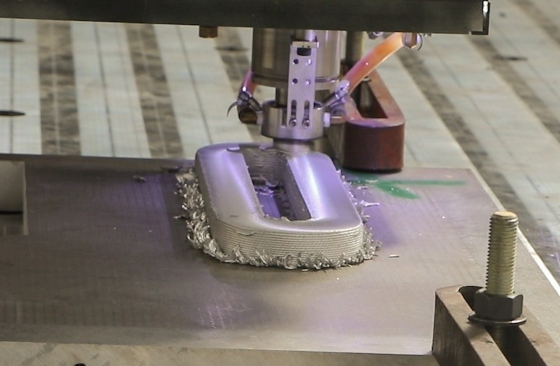

3D-printing tests are run on the giant Jointless Hull machine at the Rock Island Arsenal Joint Manufacturing and Technology Center in Illinois. [Credit: U.S. Army photo by Kendall Swank]

Main story by Kendall Swank, U.S. Army

Even before the Rock Island Arsenal Joint Manufacturing and Technology Center (RIA-JMTC) has officially unveiled its newest modernization effort, the technology used to 3D print large metal components has won awards at North America's premier military, aerospace, and defense 3D-printing event.

"[The technology] opens up the aperture of our capabilities," said Edward Flinn, director of the Advanced Manufacturing Center of Excellence at RIA-JMTC. "This is a one-of-a-kind device."

The so-called Jointless Hull machine (made with the aim of 3D printing a tank hull in one piece) is the world's largest additive and subtractive manufacturing apparatus. It's located within the 3 million square feet of RIA-JMTC's footprint at Rock Island Arsenal in Illinois and earned the 2024 Technical Achievement Award for 3D-Printing Innovation at the 8th Annual Military Additive Manufacturing Summit & Technology Showcase.

The equipment was built for the U.S. Army in conjunction with RIA-JMTC, the U.S. Army Ground Systems Center, Ingersoll Machine Tool, the Applied Science and Technology Research Organization of America, Siemens, and LIFT. The Jointless Hull is operated by the extremely talented workforce of Department of the Army civilians and transforms the manufacturing capabilities at RIA-JMTC.

"To be able to 3D print something that is forging-level quality didn't exist until now," said Flinn. "In the past, except for some unique situations, it's always been a weldment or assembly using conventional techniques. The joints were always the weakest section of the part. This new system makes it possible for people to not worry about the joints or seams, because you can make it in one piece."

The advancement combines additive friction stir deposition technology developed by Meld Manufacturing, Ingersoll Machine Tool's Gantry crane system, and subtractive milling capabilities. The collective efforts result in the largest library of materials that can be directly 3D metal printed and machined without a heat-treat cycle in between.

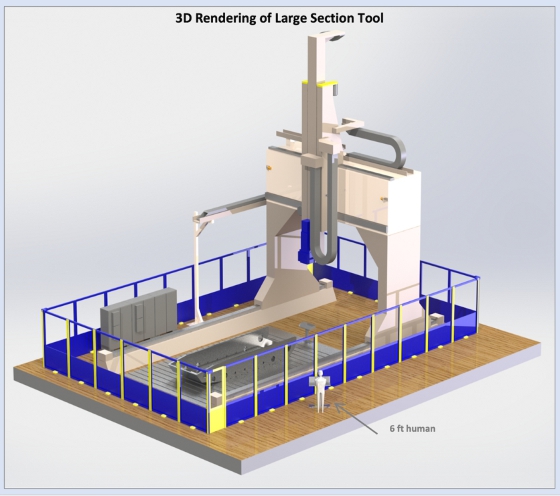

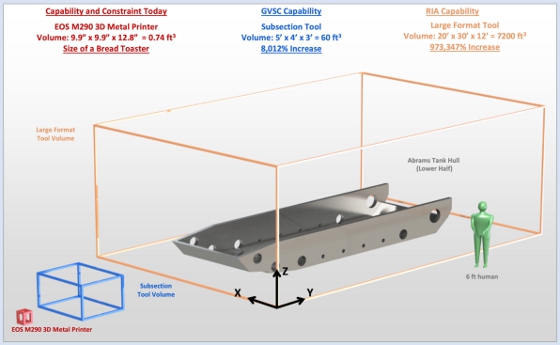

The giant hybrid additive and subtractive manufacturing machine has a print volume of 20 ft x 30 ft x 12 ft. [Credit: U.S. Army photo by Kendall Swank]

"The technology is a way to print metal with the same properties that you would get from like a blacksmith with a hammer," said Chase Cox, vice president of Meld Manufacturing. "So, you get metal hot, put pressure on it, and it forms and changes shape. The only difference here is we don't have a hammer. We have a machine that's applying the force, and we're rotating that material to get the heat built up. From there, the material can deposit much like a plastic printer."

The process opens new doors for metal manufacturing for the U.S. Army. The Jointless Hull machine has a print volume of 20 ft x 30 ft x 12 ft, which opens the door for larger metal 3D prints down the road and could eventually build equipment the size of tank hulls with minimal use of traditional manufacturing processes.

MELD Manufacturing's MELD technology was selected to produce the world's largest 3D metal printer as part of the U.S. Army's Jointless Hull Program. [Photos credit: MELD Manufacturing]

The prototype equipment is part of the U.S. Army's new 15-year, $4.5 billion modernization plan across its organic industrial base (OIB). Army Materiel Command will oversee the transition at RIA-JMTC, which will include a new thick aluminum line, upgrades to the factory's foundry, and several other projects scheduled ahead of 2030 and beyond.

The additive and subtractive manufacturing machine includes milling capabilities that shape the final printed piece. [Credit: U.S. Army photo by Kendall Swank]

"RIA-JMTC is extremely proud of this great achievement in manufacturing by our team and partners, and we're excited to be paving a path forward with this technology," said Col. David Guida, commanding officer of RIA-JMTC. "Not only will it allow us to utilize this type of equipment before anyone else in the world, but it will also make sure our organization continues leading the way for the U.S. Army's modernization efforts across the OIB."

The future capabilities of the Jointless Hull could lead to advancements in 3D metal printing technology, which would align with RIA-JMTC's vision of producing high-quality, on-time readiness solutions for the warfighter while modernizing for the next fight. The machine could eventually run around the clock without employee supervision, decreasing the time it takes to manufacture and deliver products, while still producing stronger and more reliable components.

"[This project is] a representation of the successes we can have when the government and [private] industry work together to create something new and innovative," said Larry Holmes, director of government relations for ASTRO America. "The U.S. Army is taking huge strides in developing new manufacturing technologies, but it also requires the help of people in the industry."

SIDEBAR: Friction stir welding tech + 3D printing = MELD technology

By Designfax

In order to understand friction stir 3D printing, it is worthwhile to take a look at how friction stir welding, a companion technology, works.

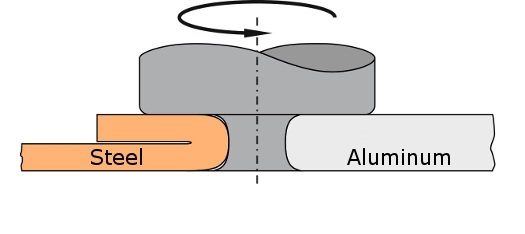

In friction stir welding, a pin tool spins and presses to make metal flow without melting. [Credit: University of Stuttgart in Germany/TLB]

A friction stir welding machine looks and acts like a cross between a drill press and a sewing machine. Lowered onto two metal sheets sitting side by side, the "drill bit," or in this case pin tool, spins against both edges. As it travels along, the pin creates friction that heats, mixes, and joins the alloys without melting them.

In one joining method, the friction stir welding process involves folding a thinner steel sheet to create a uniform butt joint with thicker aluminum. [Credit: University of Stuttgart in Germany/TLB]

Friction stir welding is a pressure welding process for joining light metals -- even similar metals of different thicknesses or two dissimilar metals (steel and aluminum, for example). One valuable benefit is that the process produces high-strength joints. Another benefit is that joints made from dissimilar materials can be made with minimal extra edging, an improvement over traditional overlap welding processes. A combined overlap and butt joint can also be made in just one welding pass.

Now imagine that a friction stir weld tool (pin) is put on a 3D-printing machine that is continually fed metal feedstock (solid metal in wire, powder, or even bar form) to the head. The fricton "stirring" allows the metal to flow without melting, so the metal can be laid down in a layer. In this case, metal layers are flowed and welded together until a whole part is made.

According to MELD Manufacturing, friction stir "makes the material malleable without melting, offering stronger, better quality parts." It is a solid-state process, which means the metal never reaches its melting temperature. The company says its MELD process "deposits material at least 10 times faster than fusion-based metal additive processes. While other additive technologies may restrict your deposited material choices to a select few expensive proprietary alloys, MELD is not limited in the metal alloys that can be deposited. From aluminum to titanium and steel to nickel-based super alloys, MELD is proven to create high-quality material using the same machine and the same process."

The thermo-mechanical MELD process creates enough flow in the material to combine it and create parts that otherwise appear to be forged. It's versatile because it uses any metal. It's simple and offers predictable results. It's fast and able to print the largest parts. It is also unique in the ability to repair existing parts. MELD technology also includes subtractive manufacturing (milling) in the form of a three-axis subtractive head that shapes and cleans up the initial rough build.

Sidebar sources: MELD Manufacturing, University of Stuttgart

Published January 2024

Rate this article

View our terms of use and privacy policy